Dr. Müller Instruments GmbH & Co. KG – der Spezialist für Kurzzeitmesstechnik

- Sensoren für Druck- und Temperaturmessung mit einzigartig kurzen Reaktionszeiten

- Messtechnik für Druck, Temperatur und UV-Licht in der Fläche

- Systeme zur Kraftmessung sowie verschiedene Verstärker

- Eine große Palette an Prüfgeräten für die Explosivstoffprüfung

Hydrophon: Die Müller-Platte Nadelsonde

Piezoelektrisches Hydrophon für hochfrequente Druckmessungen von Ultraschall und Stoßwellen in Wasser. Die Müller-Platte Nadelsonde wurde 1985 an der RWTH Aachen im Rahmen einer Zusammenarbeit zwischen dem Stoßwellenlabor und dem Institut für Akustik entwickelt. Die Nadelsonde ist der Goldstandard zur Messung von niedrig energetischen Explosionswellen in Wasser. [mehr dazu]

Jetzt NEU: Optisches Hydrophon

Einzigartiges optisches Hydrophon – robust, membranfrei, breitbandig – entwickelt für Ultraschall-Anwendungen im Pa-to-MPa-Bereich. Es eignet sich besonders für die in der Medizintechnik und Industrie erforderliche Charakterisierung von Ultraschallgeräten. Mit Hilfe der patentierten Techologie ist der Sensor immun gegen Beschädigungen durch Hochdruckamplituden. [mehr dazu]

Drucksensoren für Flüssigkeiten und Gase

Hierzu bieten wir zwei piezoelektrische Sondentypen an. Zum einen die Müller-Platte Nadelsonde, seit 20 Jahren der Goldstandard für Wasserstoßwellenmessung mit einer Anstiegszeit von 50 ns, bekannt für die Vermessung von Nierenstein-Zertrümmerern o.ä. und die ebenso schnellen Drucksonden vom Typ M60-1L und M60-3L sowie die Sonden M60-3 und M100-1 für die Anwendung in Gasen. [mehr dazu]

Druckmessfolien FUJIFILM PRESCALE

Flächenpressungen messen leicht gemacht – Flächenpressungen oder Druckverteilungen in den unterschiedlichsten Anwendungsbereichen können seit Jahren mit der weltweit einzigartigen Fuji-Druckmessfolie bestimmt werden. Der Messbereich reicht von 0,05 bis 300 MPa. [mehr dazu]

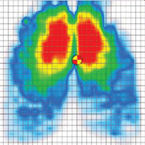

Elektronische Druckmessfolien: Tactilus, die elektronische Druckmessfolie

Im Bereich der elektronischen Druckmessfolien ist Sensor Products Inc. seit Jahren unser Partner. SPI ist in den USA der langjährige Experte im Bereich der flächigen Druckmesstechnik. Mit Tactilus, einem Matrixsensor auf piezorestiver Basis, der als dünne Matte zwischen alle Körper zur Flächenpressungsmessung platziert werden kann, eröffnen sich zahlreiche Möglichkeiten. [mehr dazu]

Temperatursensoren für die Wärmestrommessung

Wählen Sie zwischen zwei verschiedenen Sensoren: Die robusten Thermoelemente mit Ansprechzeiten im Mikrosekundenbereich, können nahtlos in die Oberfläche eingepasst werden können. Die Nickel-Dünnschichtsonden sind hochempfindlich, mit kurzer Ansprechzeit und innenliegenden Anschlüssen. Die Thermoelemente bieten die Möglichkeit dynamischer Wärmestrombestimmung. [mehr dazu]

Wärmemessfolien FUJIFILM THERMOSCALE – Wärmeströme leicht gemessen

Mit der neuen Folie Thermoscale Temperaturmessfolie erweitern wir unsere Produktpalette um eine Folie, die mehr kann als die Temperatur zu messen. Thermoscale misst den Wärmestrom. Ein Wärmestrom setzt sich aus den Parametern Temperatur und Zeit zusammen. Gleichzeitig muss ein gleichmäßiger Anpressdruck sichergestellt sein. Dadurch sind Druckmessfolien neben Wärmemessfolien unverzichtbar. [mehr dazu]

UV-Lichtmessfolie UVSCALE – Bestrahlungen leicht gemessen

Mit der neuen Folie UVSCALE erweitert Fuji seine Produktpalette um eine weitere Messfolie, die die Bestrahlung von UV-Licht je nach UV-Licht von 4 bis 100.000 mJ/cm² in einem Wellenlängenbereich von 200 bis 420 nm messen kann. Seit 30 Jahren liefert Müller Instruments FujiFilm Prescale, die Druckmessfolie zur Bestimmung der Flächenpressung. Sie ist heute in allen Industriezweigen im Einsatz. [mehr dazu]

Ringkraftmesser – das etablierte Kraftmessgerät

Zug- und Druckkraftmesser auf kleinem Raum: Tiedemann Ringkraftmesser – auch Dynamometer genannt – sind hochpräzise mechanische Kraftmessgeräte für quasistatische Zug- und Druckkräfte. Die Messbereiche, der von Ministerpräsident Goppel mit einer Goldmedaille ausgezeichneten Ringkraftmesser, reichen von 50 N bis 200 kN. [mehr dazu]

Verstärker

Dr. Müller Instruments bietet die passenden Verstärker für die Druck und Temperatur-Sonden im Frequenzbereich bis 1 bzw. 10 MHz. Der Ladungsverstärker MCPA für piezoelektrischen Drucksensoren ermöglicht z.B. lange Kabel bis 150 m. Der Spannungsverstärker ist für Thermoelemente und Nadelsonden im Ultraschallfeld gedacht, der MFA 1000 für Temperatursensoren mit Sensorspeisung. [mehr dazu]

Explosivstoff-Prüfsysteme

Zur Untersuchung von Explosivstoffen bieten wir über unseren Partner OZM vor allem für den deutschsprachigen Raum eine vollständige Produktpalette an. Untersuchungsmethoden wie Stabilitäts-, Empfindlichkeits- und Wirksamkeitstests über Detonationskammern bis zu verschiedenen Lagersystemen sind Teil dieses Produktprogramms. [mehr dazu]

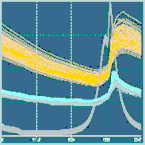

SATURN – Die neue Generation von Transientenrekordern

Die Produktgruppe der Saturn Transientenrekorder setzt neue Standards im Bereich der Datenerfassung. Das skalierbare und vielseitige System wurde für eine Reihe verschiedener Anwendungen entwickelt und wird für hoch synchrone Messungen mit höchster Präzision und Geschwindigkeit eingesetzt. [mehr dazu]