CALTEST Calibration- and Analysis System

Calibration System for FUJIFILM Prescale

FUJIFILM’s pressure sensitive Prescale film is an important tool for the determination of contact pressure. It is ideal for fast qualitative evaluations, as for quantitative measurement, control experiments should to be done prior to the measurement, which are then transferred to calibration curves.

Tiedemann has developed a calibration system, which includes all necessary tools:

- Calibration Plunger KV with two cylindrical, plain-polished plungers with well know front areas to press the material sample and the film

- Compression Device BELV, individually equipped with a Tiedemann ring dynamometer

- Hand Cutting tool SV to cut the Prescale film in the diameter of the Calibration Plunger KV

- Punching toll PV to cut thicker structural material in the diameter if the Calibration Plunger

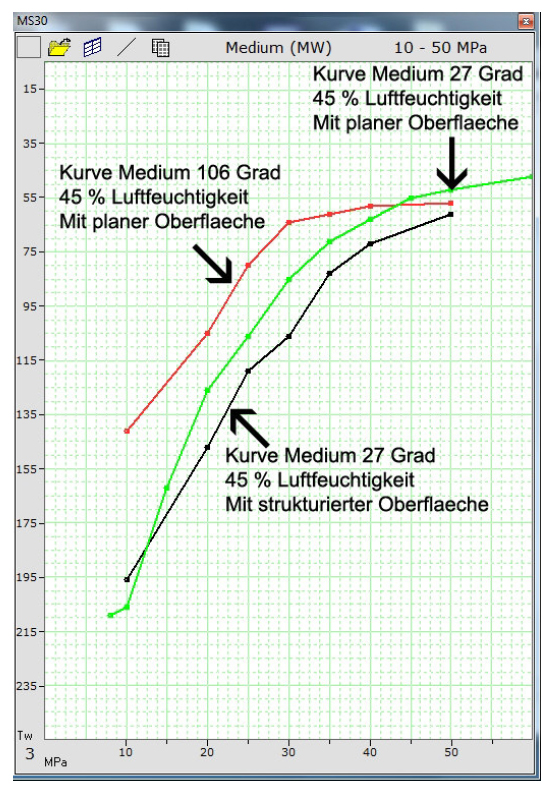

Calibrations with Different Press Materials

The Tiedemann calibration system is made for smooth surface pressures as well as structured surrounding materials like grids or carpets. In such a case, the structure is visible on the films as well. The impression is difficult to evaluate, therefore it is recommended to place the film between these structured materials during calibration to generate an individual calibration curve for this material.

Execution of the Calibration System

Find the Right Combination of Tools

A basic configuration for surface compressions up to 50 MPa is the Compression Device BELV. Further, you choose the right Tiedemann dynamometer, the KV Calibration Plunger device plus optional the SV Hand Cutter tool. Whether a PV Punching Tool is recommended depends on the ambient structural materials. At surface pressures above 50 MPa, we must refer to your own press.

Calibration Plunger Device KV

Together with the right choice for dynamometer many pressure ranges can be reached. For higher accuracy, the bigger plunger should be used. Because the maximum load of the compression device is limited to 10 kN, you may use the calibration plunger in your own press as well.

| Characteristics of KV | KV0.5 | KV1 | KV2 | KV5 |

| Plunger diameter (mm) Plunger area (mm²) | 50.46 | 2000 | 35.68 1000 | 25.23 500 |

| 1 kN load: surface pressure (MPa) | 0.5 | 1 | 2 | 5 |

Cutting and Punching Tools

The optional tools for hand cutting SV are helpful to cut circular areas out of the pressure sensitive film or other thin materials. These circular areas fit exactly to the size of the plunger.

PV Punching Tools are also available to cut thicker materials for the right diameters. For punching the Compression Device BELV may be used as well as your own presses.

Find the Right Combination of Tools

A basic configuration for surface compressions up to 50 MPa is the Compression Device BELV. Further, you choose the right Tiedemann dynamometer, the KV Calibration Plunger device plus optional the SV Hand Cutter tool. Whether a PV Punching Tool is recommended depends on the ambient structural materials. At surface pressures above 50 MPa, we must refer to your own press.

Download

Brochure Tiedemann CALTEST System [PDF, 1.916 KB]

Calibration Sequence picture series [PDF, 1.545 KB]