Laser Hydrophone

Application

This is a robust, large-bandwidth membrane-free hydrophone. Designed for ultrasound sensing in the mPa to MPa regime. It is particularly suited to the characterization required for medical and industrial ultrasonics equipment. Using patented technology, the sensor is immune to damage from high pressure amplitudes. It offers superior measurement bandwidth in a small form factor.

Features

- Fiber-coupled, membrane-free optical hydrophone

- Dynamic range: Version 1: 20 mPa –1 MPa; Version 2: 1 mPa - 10 kPa

- Immunity to electromagnetic interference (EMI)

- Ultrasound frequency range from 10 Hz up to 1 MHz in air, 10 MHz in liquids

- Acoustic detection greater by a factor of 10 than present state-of-the art

- Transducer principle with a perfectly linear frequency response. Although the enclosure needs to be carefully designed to minimize its influence on the sound field, the transducer itself is not frequency dependent

- Sound detection in liquids

- Qualification for ultra-high sound pressure levels (up to 190 dB SPL)

- Since no moving inert mass is involved, the Laser Hydrophone has a true temporal impulse response.

- Inherent phase match in array configurations

- No metallic parts and glass fiber-coupled, hence operational in high electromagnetic fields.

- For water temperature up to 100°C / 60°C

Technology

For the detection of sound waves, conventional microphones use membranes or other moving parts as intermediaries between the incoming acoustic and the resulting electrical quantity. For acoustic ultrasound sensors based on piezoelectric crystals, the approach is similar: the acoustic wave mechanically deforms the crystal. In contrast, the patented idea behind the Laser Hydrophone is to exploit another, completely different property of sound: The fact that sound changes the speed of light!

In a rigid Fabry-Pérot laser interferometer consisting of two miniaturized mirrors, sound pressure changes the refractive index of the water. This alters the optical wavelength and the light transmission which consequently leads to the respective electrical signal. In contrast to conventional hydrophones, the Laser Hydrophone is the world's first system without any moving parts. No mechanically movable or physically deformable parts are involved. By consequence, the sensors exhibit a compelling frequency bandwidth, free from mechanical resonances. The sensor principle is highly sensitive. In fact, refractive index changes below 10-14 can be detected with this technology. This corresponds to pressure changes as small as 1 μPa.

Technical Data

| SENSOR: | |

| Transducer type: | Membrane-free, optical |

| Frequency range: | 10 Hz - 20 MHz |

| Dynamic pressure range: | 20 mPa - 1 MPa |

| Self-noise, BW 1 Hz @ 100 kHz | 20 mPa/1 mPa |

| Self-noise, full bandwidth: | 90 Pa |

| Sensitivity: | 12 mV/kPa/3,4 mV/Pa |

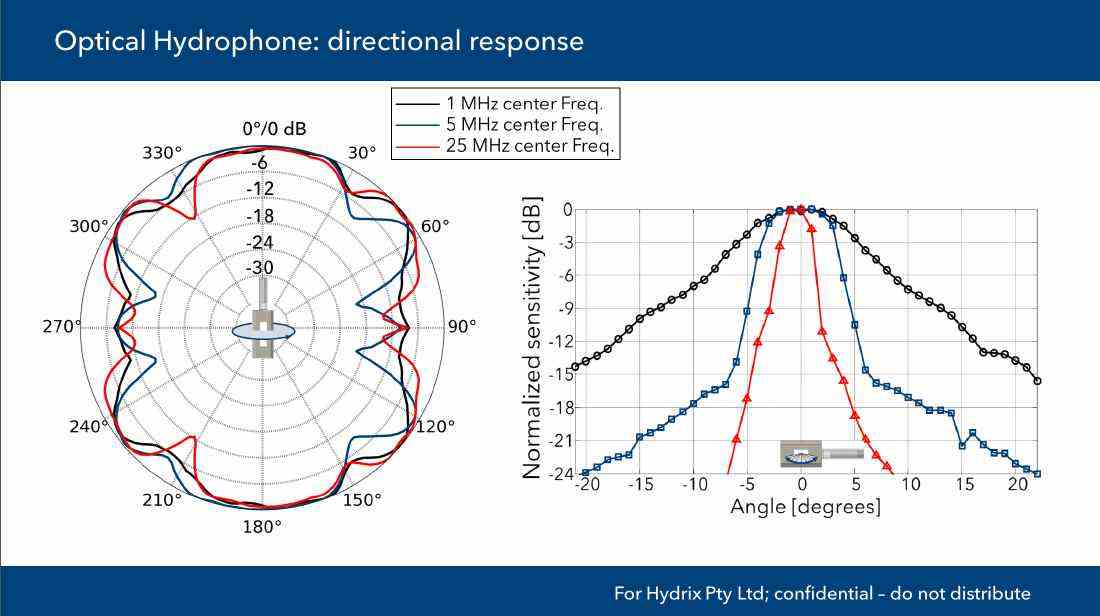

| Polar pattern: | Omnidirectional |

| GENERAL: | |

| Sensor output voltage: | ±15 V (high impedance), ± 7.5 V (50 Ohm) |

| Sensor output voltage connector: | BNC |

| Sensor output impedance: | 50 Ohm |

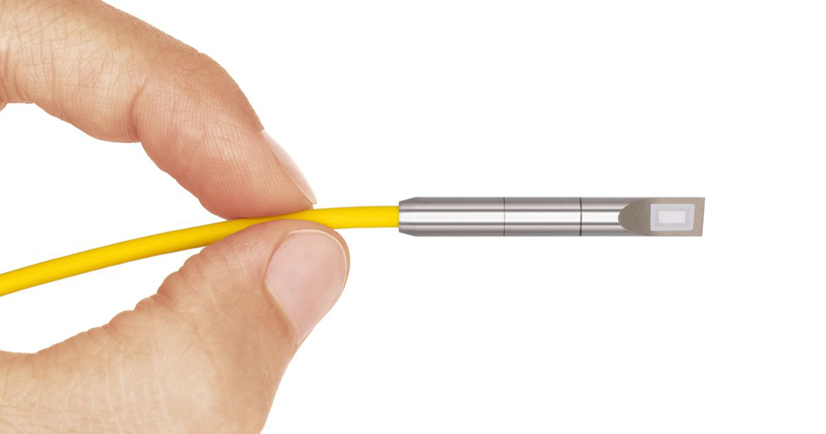

| Size of sensor head: | diameter: 6.5 mm; length: 35.4 mm |

| Weight of sensor head: | 12 g |

| Fiber cable length: | 5 m (other upon request) |

| Size of control unit: | 220 mm x 330 mm; height: 95 mm |

| Weight of control unit: | 8 kg |

| Power supply (signal conditioner): | 120/230 V ± 5%, 50/60 Hz |

| Power consumption: | <50 W |

| Operating temperature sensor head: | 5°C to 100^C / 5°C to 60°C (40 F to 140 F) |

| Operating temperature control unit: | 0°C to 50°C (30 F to 120 F) |

| Other versions for application in gases on request. |