Measurement Range and Choice of Film

There are eight types of films with their specific ranges available to cover the measurement range of 0.006 to 300 MPa. The latest type "Extreme Low" covers the range from 0.06 to 0.5 bars.

All slides are supplied in reels of 27 cm and 31 cm respectively. The length of the role depends on the sensitivity and starts at 2 m for “Ultra Extreme Low” up to 10 m for the less sensitive films.

| Film Type | Name | Layers | Range | Size |

|---|---|---|---|---|

| 5LW | Ultra Extreme Low | 2 layers | 0.006 - 0.05 MPa | 310 mm x 2 m |

| 4LW | Extreme Low | 2 layers | 0,05 - 0,2 MPa | 310 mm x 3 m |

| LLLW | Ultra Super Low | 2 layers | 0,2 - 0,6 MPa | 270 mm x 5 m |

| LLW-HT (only for 180 - 220°C) | Super Low HT | 2 layers | 0,5 - 2,5 MPa | 270 mm x 6 m |

| LLW | Super Low | 2 layers | 0,5 - 2,5 MPa | 270 mm x 6 m |

| LW | Low | 2 layers | 2,5 - 10 MPa | 270 mm x 10 m |

| MW | Medium | 2 layers | 10 - 50 MPa | 270 mm x 10 m |

| MS | Medium | 1 layer | 10 - 50 MPa | 270 mm x 10 m |

| HS | High | 1 layer | 50 - 130 MPa | 270 mm x 10 m |

| HHS | Super High | 1 layer | 130 - 300 MPa | 270 mm x 10 m |

If the expected pressure distribution cannot be covered by using only one film, more film types can be superimposed in order to expand the range.

Qualitative Evaluation

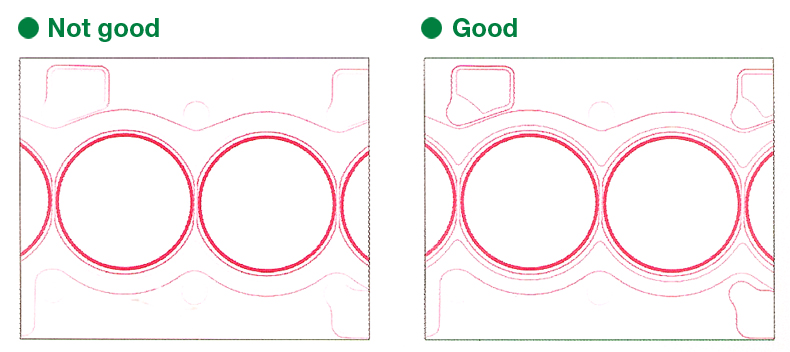

A qualitative overview of the pressure distribution is already given by inspection of the printed image. The areas with high intensity of red indicate a high surface pressure, while the areas that experienced little or no red colour indicate a lower pressure. For many applications, this qualitative statement is sufficient.

Quantitative Measurement

A quantification of the pressure from the printed images is possible at different levels of accuracy.

The user manual that accompanies each package of Fuji Prescale Film presents two different calibration curves for different types of load cycles – short load contact and continuous load. One is for a 5 seconds load cycle only, the other for constant pressure for 2 minutes. These are examples of applications for short-term and in long-term applications.

The different colours at continuous load and short-term exposure is due to the continuous rupture and to a small extent when the microcapsules are at constant load, so that the same load at a longer period of action leads to a slightly darker result. Fuji guarantees an accuracy of about 10%.

Read the Surface Pressure out of the Manual

The values of temperature and humidity affect the sensitivity of the films. In the first step, it is therefore intended, to indicate the area, which leads to curves as A, B, C, etc. for the next step.

After comparing the red intensity of the real footprint to the standard colour samples – 2nd step - you go up to the corresponding calibration curves A, B, C, etc. to get the values for the surface pressure on the pressure axis – 3rd step.

Calibration

Measurements are more accurate when the films are calibrated initially under actual experimental conditions. This is especially advantageous on structured materials, different humidities, temperatures up to 300 °C and preesing duration.

Tiedemann has developed for this purpose the complete calibration system CALTEST. In this system, the film and the surrounding material are placed between two plane-parallel stamps with a known surface area and loaded coaxially with different forces.

Quantitative Analysis with CALTEST Program

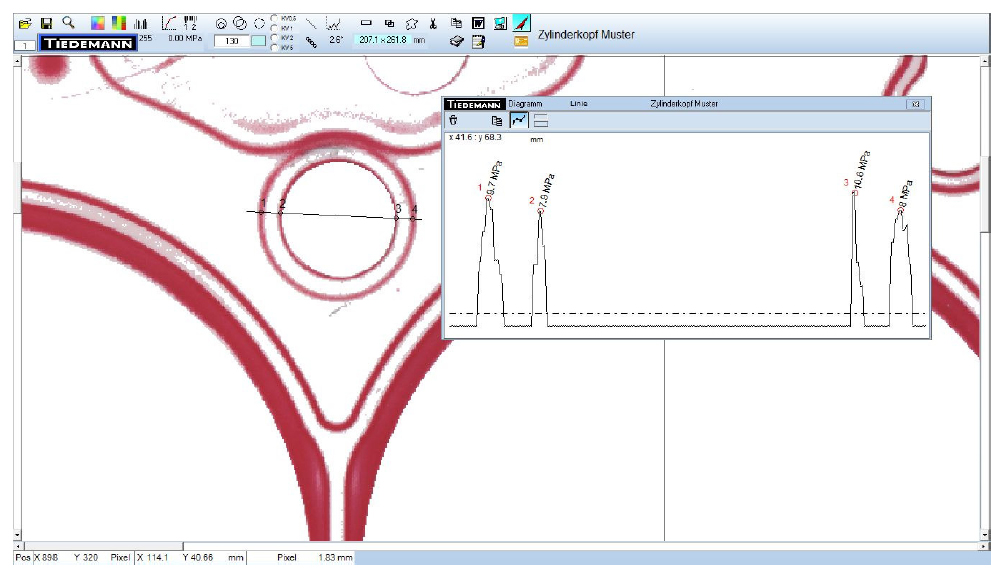

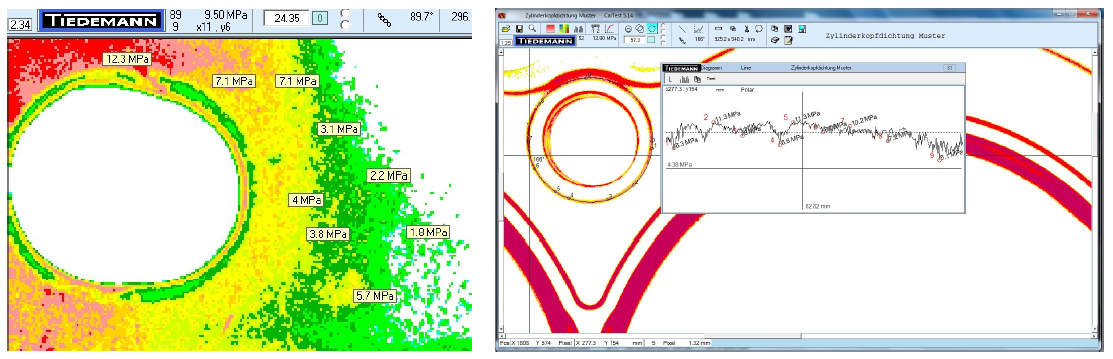

The footprint images are scanned to measure the intensity of colour change. The program then returns to the calibration curve defined for each type of film for smooth surfaces at room temperature and specific humidity. If the measuring conditions deviate from this or if the surface is structured, calibration curves can be prepared in advance.

The measured values allow a point to point or two-dimensional image processing in original or false colours. Cross section patterns, circular path calculations (O-ring), etc. can be created.

Technical Data

| FUJIFILM PRESCALE PRESSURE INDICATING FILM: | |

|---|---|

| Standard Accuracy: | +/- 10% at 23°C, 65 % rel. Humidity (RH) |

| Spatial Resolution: | 30 μm |

| Temperature of calibration curves: | 20 °C to 35 °C; applications up to 300°C are possible |

| Recommended Humidity: | 35 % RH to 80 % RH |

| Film Thickness: | 1 layer type 90 μm, 2 layer type 110 μm |

| CALTEST ANALYSIS PROGRAM: | |

|---|---|

| Operating system: | Windows XP, 7, 8, 10 |

| Languages: | german and english |

| Saved Calibration curves: | All pressure films, smooth surfaces, room temperature, 40% and 60% humidity, pressing duration 60 s |

| Scanner: | All scanners possible, saved calibration curves are valid for Tiedemann DIN A3 scanner only |

| Free Updates: | Covered by licence contract |

| Delivery: | Software-CD, A3 Scanner, 2 licences, manual |

| Training: | recommended, at Tiedemann or customer side |