Strain Gage Strips up to 1150°C

Unique portfolio of strain gages for -269 to 1150°C

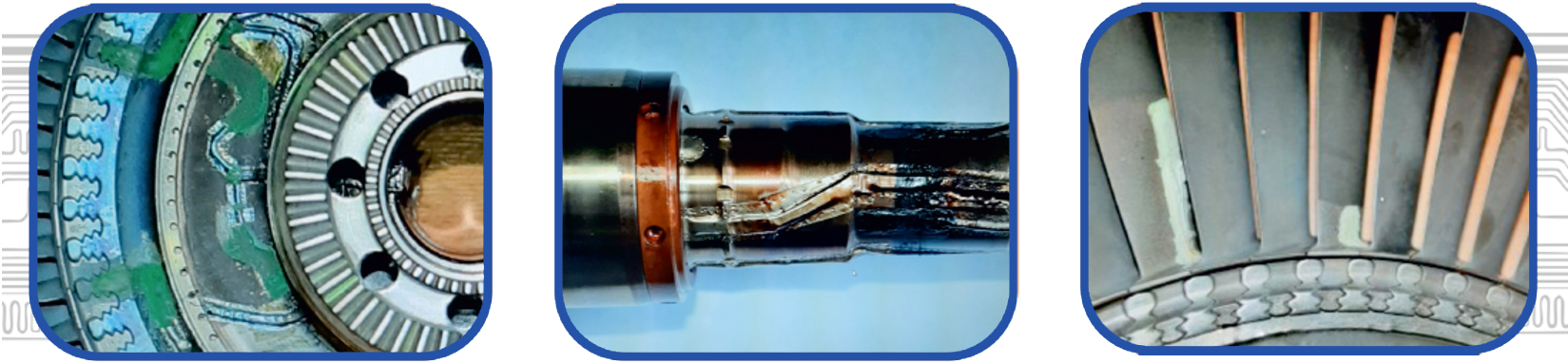

Applications

We offer here a large portfolio of strain gages for simple one-dimensional applications up to the unique highly complex three-dimensional high temperature applications in engines or power units.

Our supplier High Precision Measurements is a Ukrainian developer and manufacturer of specialized strain gauges and accessories for tensile strength measurements at elevated and high temperatures. The company manufactures strain gages for the operating temperature range from -269 to +1150°C.

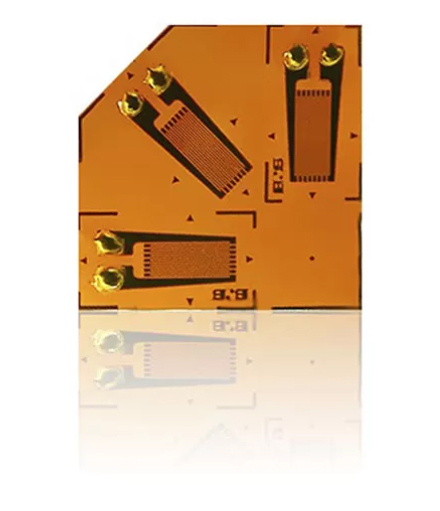

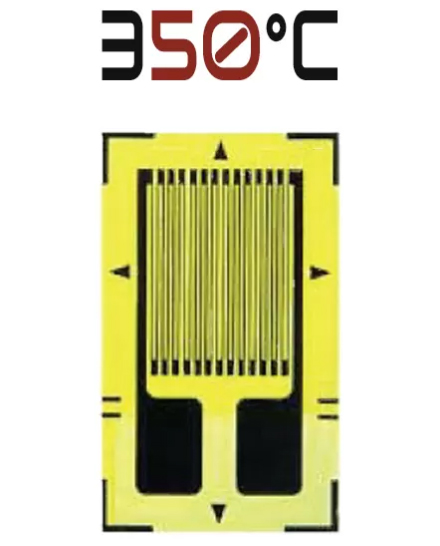

BAB series (350°C)

BAB series foil strain gages are produced from Karma alloy on a fiberglass-reinforced polyimide backing. In comparison with conventional Constantan alloy, Karma alloy has almost linear thermal output in -20…+250°C temperature range. Special backing provides excellent isolating qualities at -269…+250°C long-term and up to +350°C for short-term. These strain gages are supplied fully covered with a protective polyimide film, and with high-temperature lead wires.

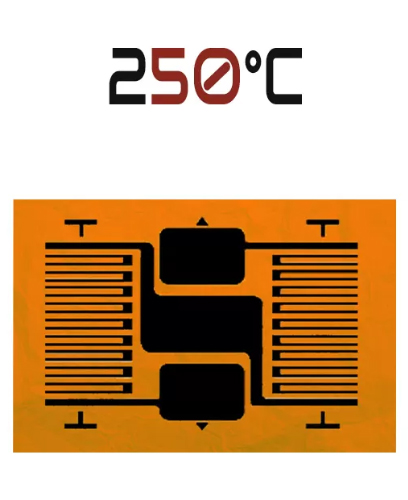

BQ250 series (250°C)

BQ250 is a Karma alloy foil based series strain gage, supplied on a special phenolic-soaked paper backing. This backing ensures extended temperature range of -269…+250°C along with perfect adhesion properties. Also, due to the flexible backing, BQ250 series gages can be installed on surfaces with complex geometries (small radius curves, thin tubes, etc.). After installation, a proper humidity and moisture protection must be ensured for this series gages, e.g., using our special protective glues.

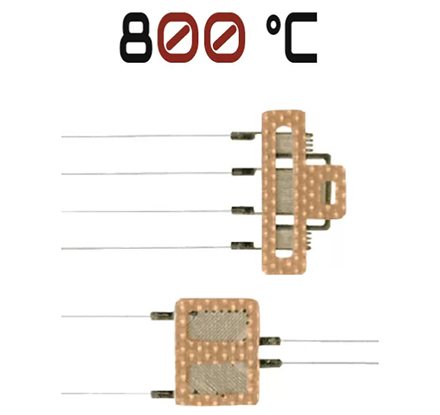

TG series (800°C)

TG series strain gages are produced from iron-chromium-aluminum (Fe-Cr-Al) alloy foil by wet etching process. They are dedicated for the measurements of static deformations and mechanical tensions in the ‑269…+800°С temperature range. Installation of the gages on the test object is done with a special high-temperature ceramic glue, e.g., GT-900.

While using TG series strain gages, temperature compensation is done by connecting the same strain gage in the adjacent branch of the measuring circuit. This allows to reach higher precision of the measurement.

TG series strain gages are shipped on the temporary fiberglass-reinforced PTFE backing, which helps to keep the shape of the gage during the installation process. After installation the temporary backing is removed.

Each lead wire has electric resistance of 10 Ohms. TG gage resistance should be measured at the center of the lead wires (25 mm from the loose end), then the measured resistance will be 350±0.3% Ohm.

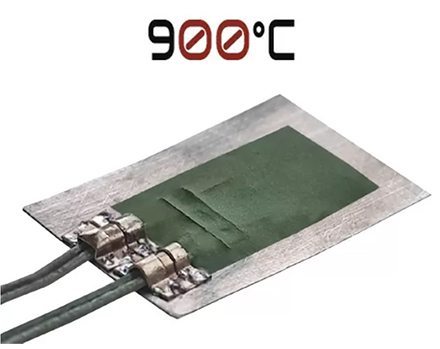

WTN series

Weldable high temperature strain gages are dedicated for measurements of deformations in the details of machinery and equipment under dynamic loads in ‑269…+900°C temperature range.

These gages are intended for installation in places where bonding with ceramic cements is not possible either due to complication in surface preparation (polishing, degreasing, etc.) or due to large dimensions of the test object (cannot be thermally treated for cement curing).

Construction-wise a WTN series strain gage is a STN series wire strain gage, installed on a small piece of thin metal foil with ceramic cement and protected with organosilicon varnish.

Sensitive grid of the gage is made of 20…30 um diameter nickel-chromium wire.

Backing material is an oxidation and corrosive resistant nickel-chromium superalloy. This material is selected to match the thermal expansion coefficient of the sensitive grid.

Sensitive grid is installed on the backing using high temperature ceramic cement, applicable for long-term operation at 900°C. Ceramic cement also acts as an insulator layer between backing and the grid. Cement layer is protected against humidity with an organosilicon varnish.

Lead wires are made in a 2-core chromel/alumel cable in silica braid sheath. Typical diameter of the cores is 0.3 mm, but can be changed on demand. Typical length of the lead wires is 100 mm.

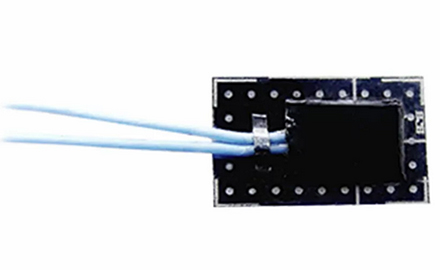

HKB series

HKB series strain gages are weldable strain gages with IP67 protection class. They are used in harsh conditions, when standard bonding of the gages is impossible due to high humidity, impossibility to clean the test object, etc. These strain gages are installed on the test object using dot welding machine. Operating temperatures range is -30…+250°C.

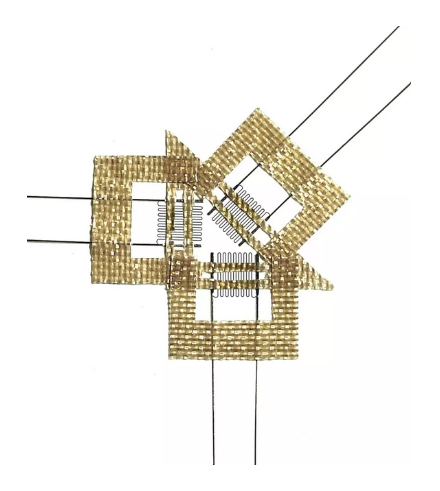

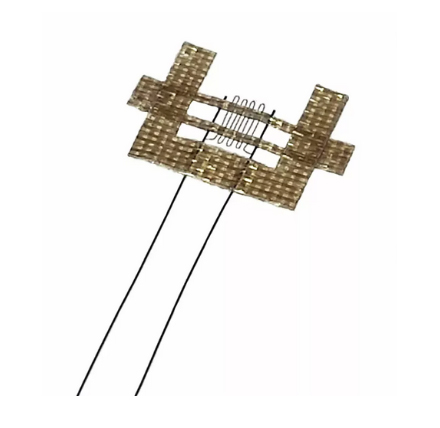

Wire rosettes

Bondable high temperature gages are intended for measurements of deformations in the details of machinery and equipment, including jet engines, under static and dynamic loads in -269…+900°C temperature range.

CA type rosettes consist of three independent sensitive grids, oriented at 0°- 45°-90° or 0°- 60°-120° and are intended for determination of complexly oriented deformations.

BA wosettes consist of two independent sensitive grids, oriented in different ways such as: T-type, L-type and V-type.

Gages are to be installed on the surface of the test object using ceramic cement adhesive or alumina flame spray method.

Gages are provided on the temporary fiberglass-reinforced PTFE carrier, which is subject to removal during installation of the strain gage.

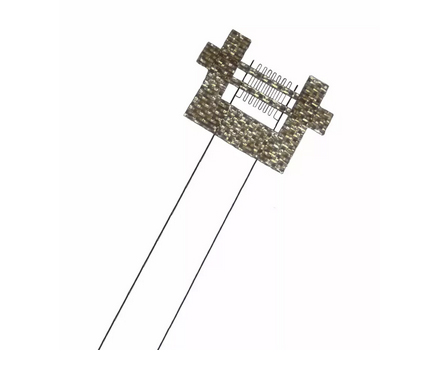

STF series

Fe-Cr-Al alloy gages are designed for the use in the widest operating temperature range. These bondable high-temperature wire strain gages are dedicated for measurements of deformations in the details of machinery and equipment, including jet engines, under static and dynamic loads up to +1150°C temperature range. Sensitive grid of the gage is made of 20…30 um diameter iron-chromium-aluminum alloy wire. Sensitive grid is fixed on the temporary backing, possible in two variants: filter paper or fiberglass-reinforced PTFE. Lead wires are made of ribbon or flat wire with 0.07…0.15 mm diameter. Material of the lead wires correlates with the sensitive grid material and is also iron-chromium-aluminum based.

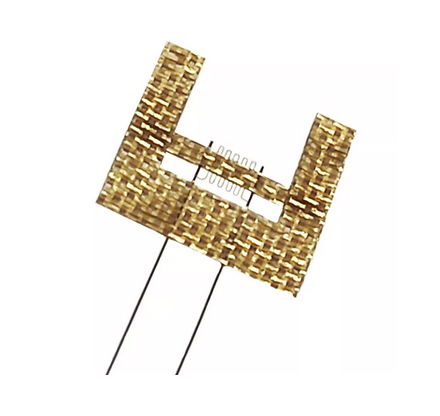

STN series

Most common type of bondable high-temperature wire strain gages for static and dynamic loads in the temperature range up to +900°C. Sensitive grid of the gage is made of 20…30 um diameter nickel-chromium alloy wire. Sensitive grid is fixed on the temporary backing, possible in two variants: filter paper or fiberglass-reinforced PTFE. Lead wires are made of ribbon or flat wire with 0.07…0.15 mm diameter. Material of the lead wires correlates with the sensitive grid material and also nickel-chromium based.

STP series

Platinum-tungsten based wire strain gages demonstrate perfect performance under dynamic loads in the temperture range up to +1150°C. Sensitive grid of these gage is made of 20…30 um diameter platinum-tungsten alloy wire. Sensitive grid is fixed on the temporary backing, possible in two variants: filter paper or fiberglass-reinforced PTFE. Lead wires are made of ribbon or flat wire with 0.07…0.15 mm diameter. Material of the lead wires correlates with the sensitive grid material and is also platinum-tungsten based.

Technical Data

You can find more details including all technical data on the various strain gauges for each type in the download area below this page.

Download

- Typical Applications (pdf, 8576 KB)

- HPM Product Catalog (pdf, 5558 KB)

- Example_application_1 (pdf, 261 KB)

- Example_application_2 (pdf, 721 KB)

- Gages STF (pdf, 279 KB)

- Gages STN (pdf, 284 KB)

- Gages STN_CA (pdf, 337 KB)

- Gages STP (pdf, 284 KB)

- Gages WTN (pdf, 157 KB)

- Reference Siemens Energy (pdf, 58 KB)

- Reference TEI (pdf, 243 KB)