Principle and Evaluation

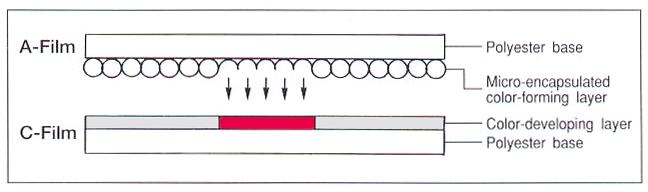

The Prescale films are produced as a 1 – and/or 2-layer film. The 2-layer types have micro-capsules applied on one foil and on the other film is the developer layer. To measure the matte layer side of the film are facing each other - the shiny side of the polyester film has to show to the outside. Each of the two films has a thickness of about 90 microns and can be cut with scissors to the desired size.

With increasing load, no reaction will appear in any given film type and then if the load increases and the first micro-capsules burst, the developer layer at the 2-layer film become slightly reddish. With further load increase, more micro-capsules will burst. This continues until all the capsules have burst, which leads then to a dark red colour of the developer layer. The intensity of the red colour thus provides a measure of the surface pressure.

Since the microcapsule layer is no longer needed after the measurement, the developer layer provides a non-erasable document.

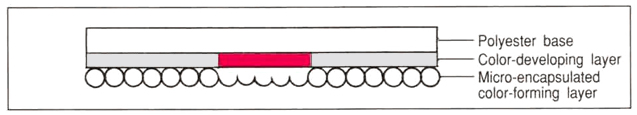

At the 1-layer film the colour forming micro-capsules and the developer are on the same slide. Under a defined pressure load, the capsules burst and discolour the film proportional to the load. Thus, you only have to put a single film with thickness 0.11 mm between the components to be investigated, which leads to measurements that are more accurate over the 2-layer type.

However, at risk of pollution (oil, chemicals or moisture), an enclosed second crystal-clear film should be used to cover the dull side of the film. The advantage of the single film is then neutralised.

After measuring the 1-layer pressure indicating film has to be protected against inadvertent load.